Solutions

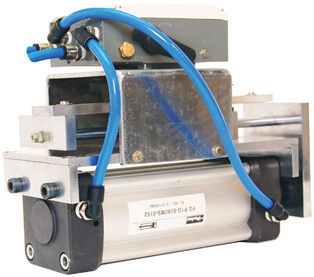

Pneumatic /Electro-Pneumatic Positioning CylinderARVI HITECH is proud to introduce new generation pneumatic positioning cylinder with the following features.

* No Extended Piston Rod

* Conforming to ISO mounting standards

* Friction Less Bearing

* Precise calibration with simple SPAN and ZERO adjustments

* Vibration resistant and Robust Design

* Aesthetic Look and Feel

* Reverse acting type available

* Corrosion resistant with hard chrome plated / aluminium linkages

* Position transmitter (4 to 20 mA DC)

Control Signal Options

* 3 to 15 PSIG

* 4 to 20 mA

* HART

* PROFIBUS

Enquiry

Pneumatic Control Panels

We make custom Pneumatic and Electro-Pneumatic panels based on customer requirement. Our enclosures are IP65 protected. From the simplest panel to the most complex of circuits, we have our team of engineers who can design the panel and make it for our customers. We also use cabinet coolers with vortex technology where conventional refrigeration coolers cannot be used. This makes our panels to be used in the harsh environments as well.

We make custom Pneumatic and Electro-Pneumatic panels based on customer requirement. Our enclosures are IP65 protected. From the simplest panel to the most complex of circuits, we have our team of engineers who can design the panel and make it for our customers. We also use cabinet coolers with vortex technology where conventional refrigeration coolers cannot be used. This makes our panels to be used in the harsh environments as well.

Valve mounted Cylinder with Fail Safe System

Parker Valve Mounted cylinder for ready use at dampers; The whole cylinder comes with a Fail Safe system. Typical applications include Damper opening/closing, where in the event of a air failure, the air fail safe system comes into action and takes care of the cylinder actuation. The cylinder confirms to ISO standard. All components of the Fail safe system are enclosed in a control panel which is IP65 protected with Electrical and Pneumatic Bulk Heads for all sides. This gives ease of use to customer without disturbing the individual components of the Fail safe system.

Parker Valve Mounted cylinder for ready use at dampers; The whole cylinder comes with a Fail Safe system. Typical applications include Damper opening/closing, where in the event of a air failure, the air fail safe system comes into action and takes care of the cylinder actuation. The cylinder confirms to ISO standard. All components of the Fail safe system are enclosed in a control panel which is IP65 protected with Electrical and Pneumatic Bulk Heads for all sides. This gives ease of use to customer without disturbing the individual components of the Fail safe system.

Parker Hydraulic power pack

* Vertical design saves floor space

* Submerged pump for quiet operation and elimination of potential leak point

* Precision pump mounting adaptors to ensure proper alignment and operation

* Suction strainer on inlet protects pump from contamination

* Pressure gauge with shut-off and oil level gauge with thermometer for improved diagnostics

* Standard safety relief valve to protect pump from system shock

* Breather/fill cap used to control ingression of contaminants

* SAE straight thread connections and ports used to prevent leaks

* Cleanout cover for easy access to reservoir

* Vertical design saves floor space

* Submerged pump for quiet operation and elimination of potential leak point

* Precision pump mounting adaptors to ensure proper alignment and operation

* Suction strainer on inlet protects pump from contamination

* Pressure gauge with shut-off and oil level gauge with thermometer for improved diagnostics

* Standard safety relief valve to protect pump from system shock

* Breather/fill cap used to control ingression of contaminants

* SAE straight thread connections and ports used to prevent leaks

* Cleanout cover for easy access to reservoir

Parker Custom Hydraulic cylinders

Custom Hydraulic Cylinder Capabilities include,

* Single or double-acting

* Bore diameters 2" to 12" in ½" increments

* Stroke lengths to 40"

* Operating pressures to 5000 p.s.i.

* Mounting ends to customer specification

* Hard chrome plated/Stainless Steel piston rods

* Standard mountings: pin eyes, flanges, trunnions and cross tubes

* Chrome plated sleeves available

* Duplex Chrome plating available

* Either NPTF, SAE O'ring, and JIC ports can be arranged at any position related to cylinder mounting

* Seals suitable for use with either petroleum or vegetable oil based fluids (-20 degrees F to +200 degrees F)

Custom Hydraulic Cylinder Capabilities include,

* Single or double-acting

* Bore diameters 2" to 12" in ½" increments

* Stroke lengths to 40"

* Operating pressures to 5000 p.s.i.

* Mounting ends to customer specification

* Hard chrome plated/Stainless Steel piston rods

* Standard mountings: pin eyes, flanges, trunnions and cross tubes

* Chrome plated sleeves available

* Duplex Chrome plating available

* Either NPTF, SAE O'ring, and JIC ports can be arranged at any position related to cylinder mounting

* Seals suitable for use with either petroleum or vegetable oil based fluids (-20 degrees F to +200 degrees F)

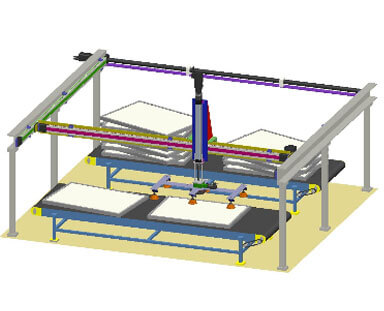

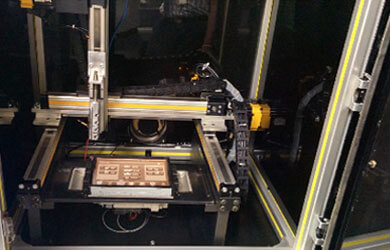

Gantry Robot

Why Gantry robots?

* Can be driven from conventional CNC controllers where Interpolation is required. (Less programming cost).

* Less maintenance cost. Spares are easily replaceable by the customer themselves unlike articulated and SCARA robots where parts / engineering cost are way too expensive and cannot not be replaced on site. Typically an articulated robot has to be serviced only by the professional service engineer deputed by the manufacturer at an exorbitantly high per/day charges. Not always the service engineer can appear within a day or two of failure. Customer usually incurs huge production losses due to downtime on above to service charges.

Applications:

* Palletizing

* Pick and place automation

* Laser cutting / Water Jet cutting

* Gluing / welding

* … and many more

Why Gantry robots?

- More area coverage and less limited by floor space constraints.

* Control from customer known PLC / PC language, (No knowledge on Inverse kinematics is required unlike articulated robots).* Can be driven from conventional CNC controllers where Interpolation is required. (Less programming cost).

* Less maintenance cost. Spares are easily replaceable by the customer themselves unlike articulated and SCARA robots where parts / engineering cost are way too expensive and cannot not be replaced on site. Typically an articulated robot has to be serviced only by the professional service engineer deputed by the manufacturer at an exorbitantly high per/day charges. Not always the service engineer can appear within a day or two of failure. Customer usually incurs huge production losses due to downtime on above to service charges.

Applications:

* Palletizing

* Pick and place automation

* Laser cutting / Water Jet cutting

* Gluing / welding

* … and many more

Customer Reference / Success Stories:

Application Examples:

Piping:

Transair is an innovative aluminium pipework system for the distribution of air, easy to assemble thanks to its rapid connection technology. With a wide product range and many accessories, Transair helps you with your air network projects by offering a modern and energy efficient solution.

Transair is an innovative aluminium pipework system for the distribution of air, easy to assemble thanks to its rapid connection technology. With a wide product range and many accessories, Transair helps you with your air network projects by offering a modern and energy efficient solution.