Compression Fittings

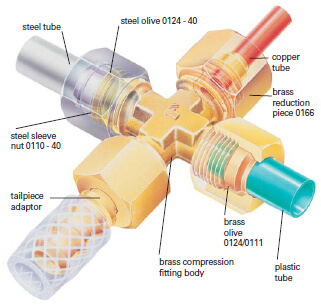

Brass Compression Fittings

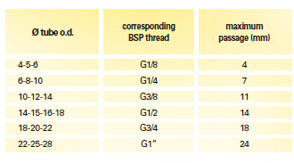

The range is called universal because it offers the maximum number of direct fitting alternatives with the minimum number of components. Tube threading and soldering a re unnecessary. Universal brass compression fittings are designed to solve all fluid distribution problems and provide a complete system of fittings suited to all types of tubing, cylinders and valves thanks to the flexibility offered by the vast range of accessories : olives, sleeve nuts, reducers, tube adaptors.

All components conform to at least one of the following standards : ISO, CETOP, AFNOR, CNOMO.

Fitting Instructions

The Legris brass compression fitting comprises a body, olive and sleeve nut. Cut the tube square, deburr inner and outer edges ; If required, any bending of the tube must be completed prior to connection. Push the sleeve nut onto the tube. For large diameters, lubricate the inside of the nut to facilitate tightening. Fit the olive onto the end of the tube, after the sleeve nut. Firmly push the tube fully home against the shoulder of the body of the fitting. Tightening of the nut enables the olive to bite into the tube and secures the fully assembled fitting.

Enquiry

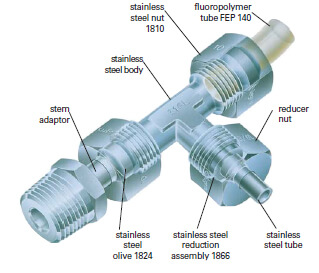

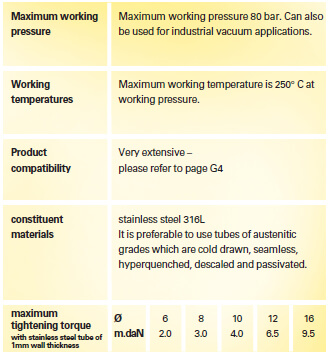

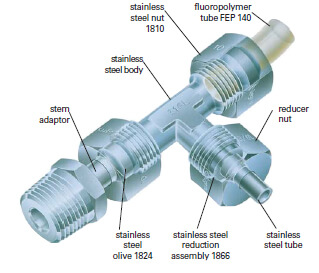

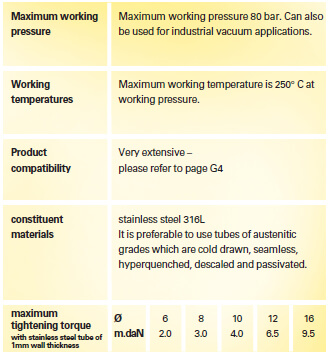

Stainless Steel Compression Fittings

Legris has used its long experience of brass compression fittings to develop a range of stainless steel compression fittings. These stainless steel fittings are resistant to aggressive or corrosive environments and fluids and withstand high temperatures and pressures. They are designed to be used at low and medium pressure and to withstand water hammer and vibration.

The stainless steel compression fitting comprises a body, an olive and a nut. The Legris stainless steel compression assembly is now ready for use.

Legris has used its long experience of brass compression fittings to develop a range of stainless steel compression fittings. These stainless steel fittings are resistant to aggressive or corrosive environments and fluids and withstand high temperatures and pressures. They are designed to be used at low and medium pressure and to withstand water hammer and vibration.

The stainless steel compression fitting comprises a body, an olive and a nut. The Legris stainless steel compression assembly is now ready for use.