Push-in Fittings

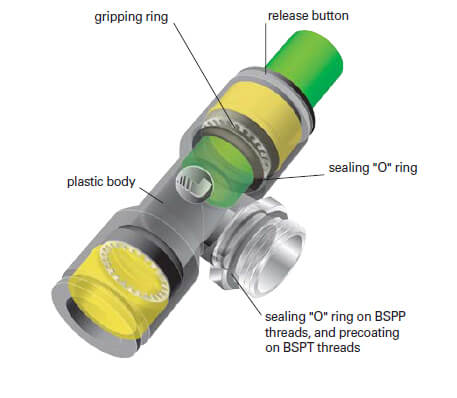

Plastic Body Fittings

Invented and launched by Legris in 1969, the LF 3000® system has become universally adopted. It has been designed using a simple and widely proven operating principle which allows instant fitting. Connection of tube to fitting is made by simply pushing the tube into the fitting, no other operation is required. Disconnection is similarly "instantaneous". Attentive to market needs, Legris has taken into account the requirements of its customers, i.e. optimization of performance, iniaturisation and appearance. In order to be utilised to its maximum capability, the LF 3000®

system is available in 3 ranges : Millions of fittings are in service throughout the world. Designed for pneumatic installations, the LF 3000 system is therefore an essential component in a wide variety of industries.

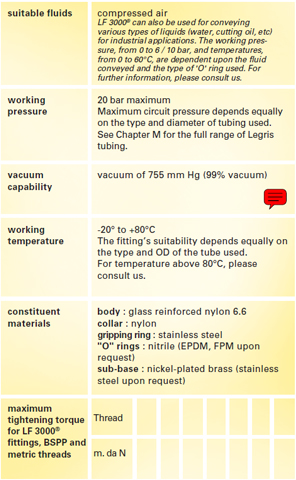

Technical Specifications

Reliable performance is dependent upon the type of tubing being used, ambient temperature and fluid conveyed together with the suitability of component materials of the fitting, according to the application.

Advantages of LF3000

Enquiry

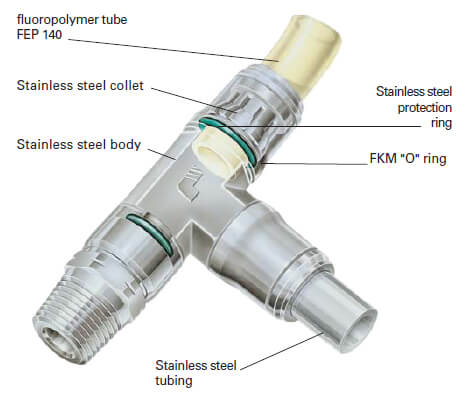

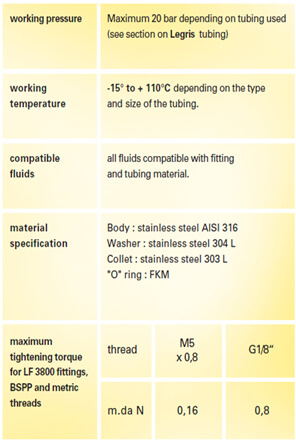

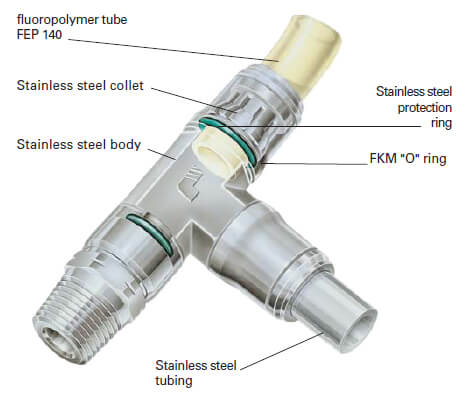

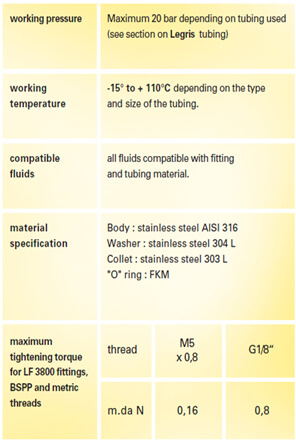

Stainless Steel Push-in Fittings

The LF 3800 range extends the advantages of push-in fittings -instant connection and disconnection – to a wider range of industrial applications. All stainless steel construction with FKM "O" ring seals, LF 3800 offers excellent resistance to aggressive environments and fluids;

To suit most applications, models are available :

The LF 3800 range extends the advantages of push-in fittings -instant connection and disconnection – to a wider range of industrial applications. All stainless steel construction with FKM "O" ring seals, LF 3800 offers excellent resistance to aggressive environments and fluids;

To suit most applications, models are available :

Function Fittings

In the field of industrial automation many functions can be controlled by purpose designed fittings. Legris Pneumatic Function Fittings have been developed to perform such functions described below.

In the field of industrial automation many functions can be controlled by purpose designed fittings. Legris Pneumatic Function Fittings have been developed to perform such functions described below.

Anti-Spark Push-in Fittings

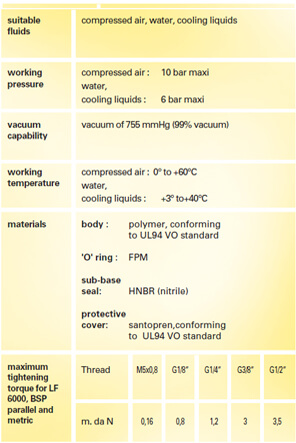

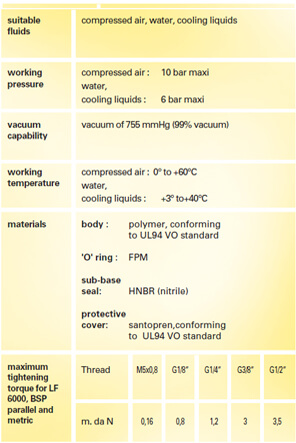

LF 6000 anti-spark push-in fittings combine LF 3000 technology with a protective cover specifically designed for excellent resistance to severe conditions of use, especially spark projections. Their light weight enables immediate connection and disconnection by hand, without tools.

A wide range is complemented by an offer of tubing that conforms to UL94 VO, thus providing a perfect solution for all applications submitted to aggressive environments and, in particular, spark projections. Thanks to these technical specifications, LF 6000 push-in fittings are perfectly suited for the requirements of the automotive process industry.

LF 6000 anti-spark push-in fittings combine LF 3000 technology with a protective cover specifically designed for excellent resistance to severe conditions of use, especially spark projections. Their light weight enables immediate connection and disconnection by hand, without tools.

A wide range is complemented by an offer of tubing that conforms to UL94 VO, thus providing a perfect solution for all applications submitted to aggressive environments and, in particular, spark projections. Thanks to these technical specifications, LF 6000 push-in fittings are perfectly suited for the requirements of the automotive process industry.

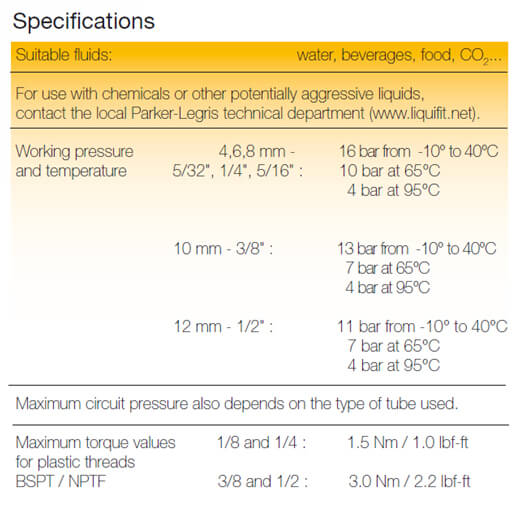

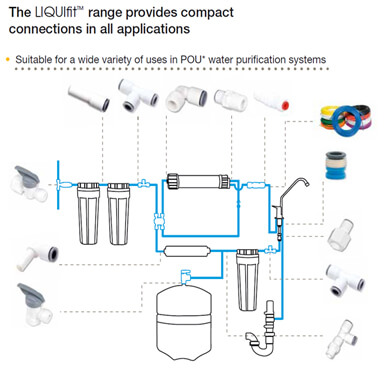

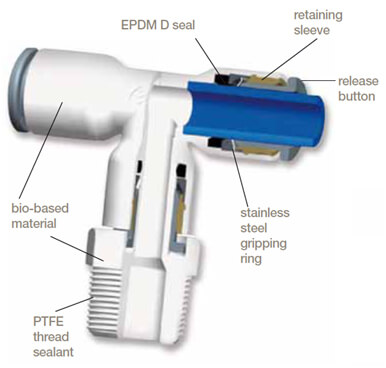

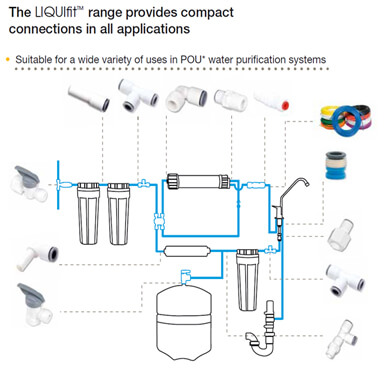

Introducing LIQUIfit™

From the Trusted Inventor of the Instant Fitting.

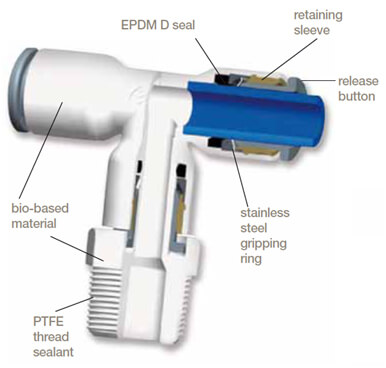

With over 40 years of experience, Legris now presents a range of leak-free, instant fittings in a bio-based compact body.

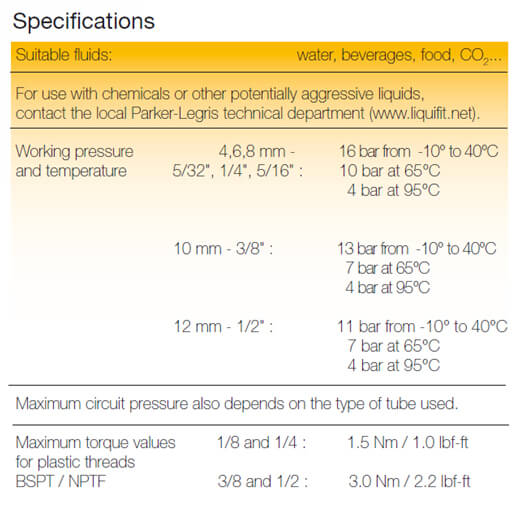

LIQUIfit™ offers:

Advantages:

Optimal sealing

High performance materials Renewable bio-based material

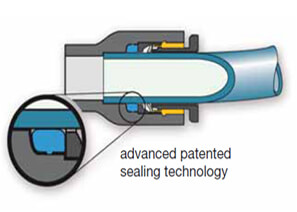

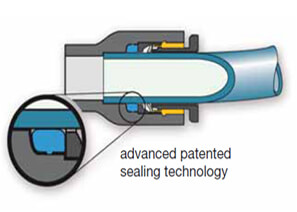

Advanced design (patented)

Innovative technology (patented)

From the Trusted Inventor of the Instant Fitting.

With over 40 years of experience, Legris now presents a range of leak-free, instant fittings in a bio-based compact body.

LIQUIfit™ offers:

Advantages:

Optimal sealing

High performance materials Renewable bio-based material

Advanced design (patented)

Innovative technology (patented)

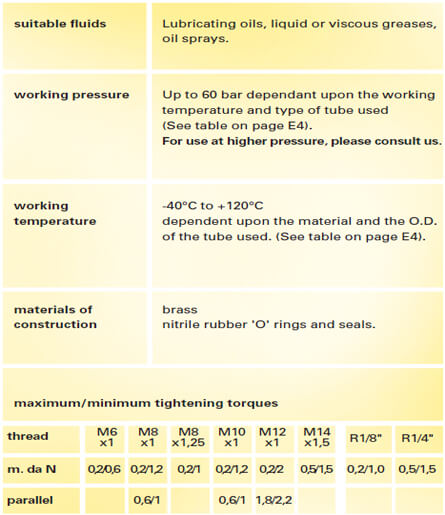

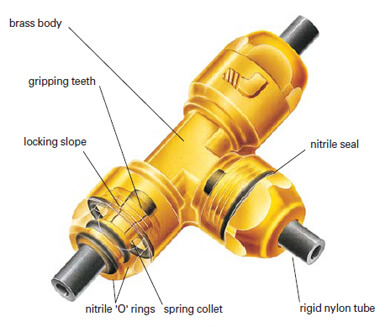

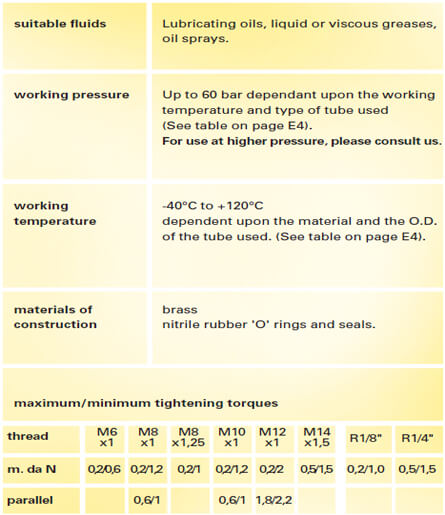

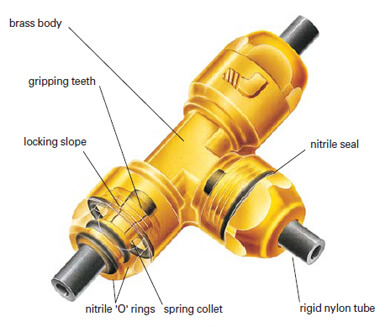

Lubrication Fittings, Brass body

This range of fittings has been designed for uses involving both rotation or linear movements which require lubrication. Designed using Legris push-in technology, this range is produced with specific applications in mind, hence its

The characteristics provide a perfect component for such applications as : Technical Specifications

Reliable performance is dependent upon the tube being used, ambient temperature and fluid conveyed together with the component materials of the fitting.

This range of fittings has been designed for uses involving both rotation or linear movements which require lubrication. Designed using Legris push-in technology, this range is produced with specific applications in mind, hence its

The characteristics provide a perfect component for such applications as : Technical Specifications

Reliable performance is dependent upon the tube being used, ambient temperature and fluid conveyed together with the component materials of the fitting.