Parker Valves

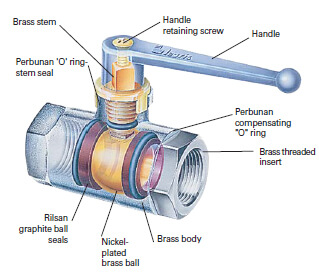

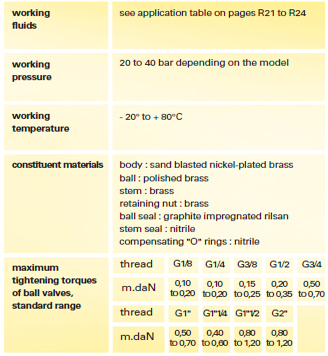

Ball Valves

The standard Legris ball valve provides a reliable means of opening and closing fluid systems. It requires a simple quarter turn of the handle to operate the two-way version, or a 180° turn for the three way version.

In the closed position the pressure of the fluid presses the ball against the seal, further ensuring the integrity of the seal. In principle, the higher the pressure, the better the seal.

Reliability

- The ball is sealed on both sides by graphite impregnated rilsan seals which are supported by perbunan compensating "O" rings. This ensures that the seal remains in contact with the ball at all times thus extending the life of the ball valve by preventing leakage should seal wear occur.

- The stem is firmly secured within a square insert on the ball and is sealed by an "O" ring.

- Light series, for low pressure applications

- Fluoropolymer series, for maximum working temperature

- Stainless steel series, for use with corrosive fluids and aggressive environments

Enquiry

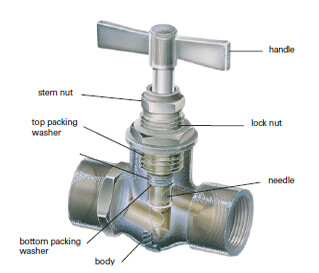

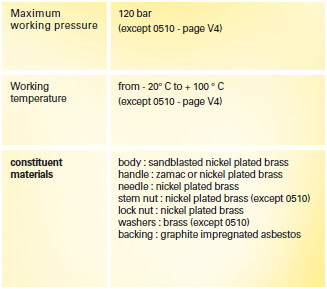

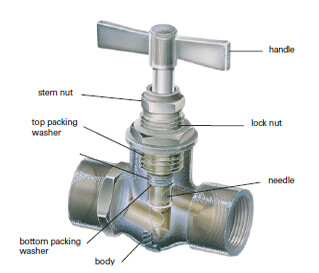

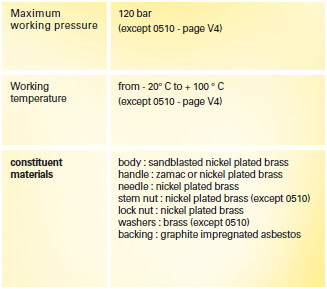

Needle Valves

Legris needle valves are designed for use where a combination of fluid control and perfect sealing is required eg.

The Legris needle valve range incorporates a wide selection of port configurations to ensure simple assembly in any system.

The following configurations are available :

Legris needle valves are designed for use where a combination of fluid control and perfect sealing is required eg.

The Legris needle valve range incorporates a wide selection of port configurations to ensure simple assembly in any system.

The following configurations are available :

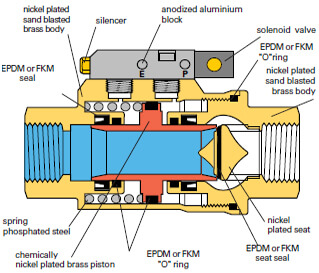

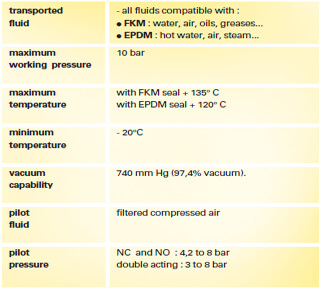

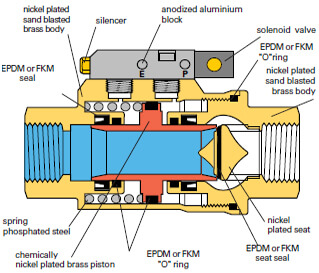

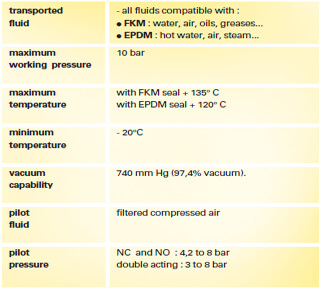

Piloted Axial Valves

Designed with a view to overcoming the limitations of traditional actuators, the Legris axial valve offers the functions of a valve fitted with an actuator.

A pneumatic automation device is fitted directly into the valve. Its operation is not affected by the up/downstream pressures of the transported fluids, which guarantees the user total safety and a vastly simplified choice.

This innovative concept is a logical extension of the Legris hand actuated ball valve range.

The range consists of the following models to suit different applications

Designed with a view to overcoming the limitations of traditional actuators, the Legris axial valve offers the functions of a valve fitted with an actuator.

A pneumatic automation device is fitted directly into the valve. Its operation is not affected by the up/downstream pressures of the transported fluids, which guarantees the user total safety and a vastly simplified choice.

This innovative concept is a logical extension of the Legris hand actuated ball valve range.

The range consists of the following models to suit different applications

- Normally closed axial valves.

- Normally open axial valves.

- Double acting axial valves

- All are available with EPDM or FKM seals.