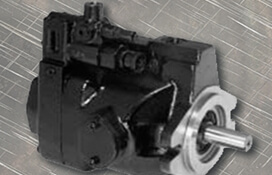

Parker Hydraulic Motors and Pumps

F11/F12 series:F11 and F12 are bent axis, fixed displacement heavyduty motor/pump series. They can be used in numerous applications in both open and closed loop circuits.

Series F11 is available in the following frame sizes and versions:

• Series F12 conforms to current ISO and SAE mounting flange and shaft end configurations. A very compact cartridge version is also available.

• Thanks to the unique spherical piston design, F11/F12 motors can be used at unusually high shaft speeds. Operating pressures to 480 bar provides for the high output power capability.

• The 40° angle between shaft and cylinder barrel allows for a very compact, lightweight motor/pump.

• The laminated piston ring offers important advantages such as low internal leakage and thermal shock resistance.

• The pump version has highly engineered valve plates for increased selfpriming speed and low noise, available with left and right hand rotation.

• The F11/F12 motors produce very high torque at start-up as well as at low speeds.

• Our unique timing gear design synchronizes shaft and cylinder barrel, making the F11/F12 very tolerant to high 'G' forces and torsional vibrations.

• Heavy duty roller bearings permit substantial external axial and radial shaft loads.

• The F11's and F12's have a simple and straightforward design with very few moving parts, making them very reliable motors/pumps.

• The unique piston locking, timing gear and bearing set-up as well as the limited number of parts add up to a very robust design with long service life and, above all, proven reliability.

General Information :

Fluid recommendations Premium quality hydraulic mineral fluid is recommended, like HLP oils to DIN 51524, part 2. Brugger- value has to be 30 N/mm2 minimum for general application and 50 N/mm2 for heavily loaded hydraulic equipment and fast cycling machines and/or high dynamic loads, measured in accordance with DIN 51 347-2. See also Document HY30-3248/UK Parker Hydraulic Fluids.

ViscosityThe normal operating viscosity should range between 16 and 100 mm2/s (cSt). Max. start-up viscosity is 800 mm2/s (cSt).

FiltrationFor maximum pump and system component functionality and life, the system should be protected from contamination by effective filtration. Fluid cleanliness should be in accordance with ISO classification ISO 4406:1999. The quality of filter elements should be in accordance with ISO standards. General hydraulic systems for satisfactory operation: Class 20/18/15, according to ISO 4406:1999.

Seals Check hydraulic fluid specification for chemical resistance of seal material. Check temperature range of seal material and compare with max. system and ambient temperature.N – Nitrile (FKM shaft seal) -25…+90 °C

B – Nitrile (NBR shaft seal) -40…+90 °C

V – FKM (FKM shaft seal) -25…+115 °C

W – Nitrile (PTFE shaft seal) -30…+90 °C

P – FKM (PTFE shaft seal) -25…+115 °C.

Description :

Benefits :