Quick Release couplers

Industrial Hydraulic & Chemical

Double Shut-Off and Straight-Thru Couplings

Parker hydraulic couplings have a wide variety of designs, each tailored to a particular application or use. However, based on the valving of the coupling, hydraulic couplings generally fall into one of two groups, either Double Shut-Off or Straight-Thru. Double Shut-Off couplings are used extensively when it is important to minimize fluid loss upon disconnection. Both halves of the coupler, the body and the nipple, contain shutoff valves. These valves open automatically when the body and nipple are connected, and close automatically when the two halves are disconnected—keeping fluid loss to a minimum. Parker Straight-Thru couplings have no valves in either half and are ideal for maximum flow application. Their smooth, open bore offers the lowest pressure drop of any quick disconnect coupling, and allows them to be thoroughly cleaned. Since there are no valves in either half, fluid flow should be shut off before the coupling is disconnected.

Rated Pressure

Rated pressure for the Parker hydraulic couplings range from 30 to 15,000 psi, depending on the coupling series, size and materials. Rated pressures as shown in this catalog are defined in the American National Standard Glossary of Terms for Fluid Power, ANSI/B93.2-1986, as “the qualified operating pressures which are recommended for a component or a system by the manufacturer.” Parker “Rated Pressures” have been established on the basis of laboratory tests which include, but are not limited to, static burst tests and multiple cycle impulse tests. System characteristics such as high cycling rates and high amplitude shocks either hydraulic or mechanical, can reduce the functioning life of a coupling, even if the system’s nominal pressure falls within the rated pressure range of the coupling. For assistance in analyzing your application, contact your nearest Parker sales office or the Quick Coupling Division in Minneapolis. Refer to the Safety Guide at the end of this catalog for considerations when selecting a Quick Coupling. Refer to the Fluid Compatibility Chart (note Table of Contents) for seal selection assistance for both Double Shut-Off and Straight-Thru couplings.

Enquiry

High Pressure

Parker's High Pressure Quick Couplings are used in high pressure applications such as portable hydraulic rams, construction, railway maintenance and jacking equipment. Manual ball-locking sleeve and thread-to-connect styles.

The following are the series of Parker High Pressure Couplers

* HO Series – Thread to connect

* CL Series – Push to connect

* FH Series – Flush faced coupler

* 3000 Series – Thread to connect

* 1141 Series – For extremely high pressures

* TC Series – with safety lock mechanism

* QHPW series – Ball Locking mechanism

* QHPA Series – Thread to connect

* SM Series – Ball locking mechanism

* HP series – Large Sizes

Parker's High Pressure Quick Couplings are used in high pressure applications such as portable hydraulic rams, construction, railway maintenance and jacking equipment. Manual ball-locking sleeve and thread-to-connect styles.

The following are the series of Parker High Pressure Couplers

* HO Series – Thread to connect

* CL Series – Push to connect

* FH Series – Flush faced coupler

* 3000 Series – Thread to connect

* 1141 Series – For extremely high pressures

* TC Series – with safety lock mechanism

* QHPW series – Ball Locking mechanism

* QHPA Series – Thread to connect

* SM Series – Ball locking mechanism

* HP series – Large Sizes

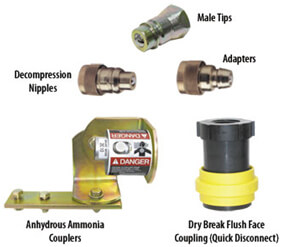

Agricultural Hydraulic Quick Release Couplers

PIONEER QUICK COUPLINGS are a product of Parker Hannifin Corporation, the largest manufacturer of hydraulic quick couplings in the world. In the Agricultural market, Pioneer is the oldest quick coupling supplier-more than 50 years. Also the largest, with the broadest product line. As a result, Pioneer is standard equipment on most farm tractors. Major manufacturers have licensed Pioneer, alone, to make quick couplings according to their patents.

PIONEER QUICK COUPLINGS are a product of Parker Hannifin Corporation, the largest manufacturer of hydraulic quick couplings in the world. In the Agricultural market, Pioneer is the oldest quick coupling supplier-more than 50 years. Also the largest, with the broadest product line. As a result, Pioneer is standard equipment on most farm tractors. Major manufacturers have licensed Pioneer, alone, to make quick couplings according to their patents.

Check Valves

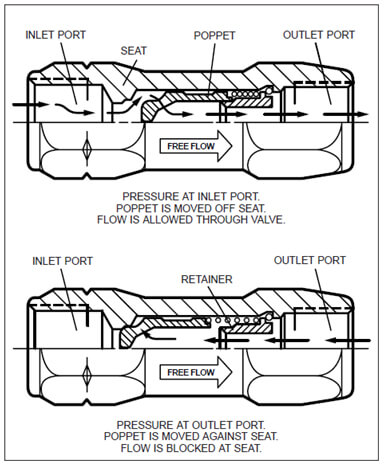

A check valve is a device specifically designed to ensure that fluid flows in one direction only. It’s used to eliminate potential damage to a hydraulic system caused by fluid back pressure.

Parker’s Bruning check valves employ several unique features that insure years of trouble-free operation. The double seat, guided poppet, oil retention groove in the poppet and poppet-guide cushion, combine to offer the finest check valve available. It’s important to note that the double seat and the cushioned poppet are exclusive to Parker.

A check valve is a device specifically designed to ensure that fluid flows in one direction only. It’s used to eliminate potential damage to a hydraulic system caused by fluid back pressure.

Parker’s Bruning check valves employ several unique features that insure years of trouble-free operation. The double seat, guided poppet, oil retention groove in the poppet and poppet-guide cushion, combine to offer the finest check valve available. It’s important to note that the double seat and the cushioned poppet are exclusive to Parker.