Hoses

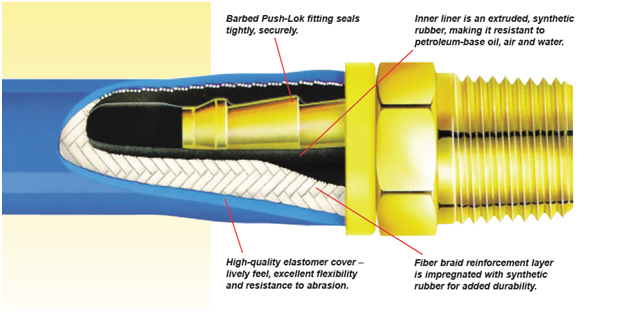

Push-Lok Hoses

The Benefits of Parker Push-Lok®

Offering easy assembly and organization The Push-Lok system is easy to use. No clamps or special tools are required during installation. And with Parker’s exclusive color code system, you can inventory, maintain and identify your hose needs easily and efficiently.

Providing exceptional value Parker Push-Lok assemblies can be made in seconds, saving valuable time and money. What’s more, Push-Lok fittings are reusable. Just replace the hose at the job site without any special tools or clamps.

Meeting all your special needs Helping you maintain a clean environment on the job is another important reason to use Parker’s Push-Lok system. Its unique seal ensures reliability and durability for clean-environment use.

Enquiry

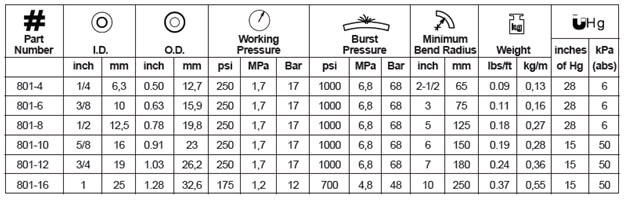

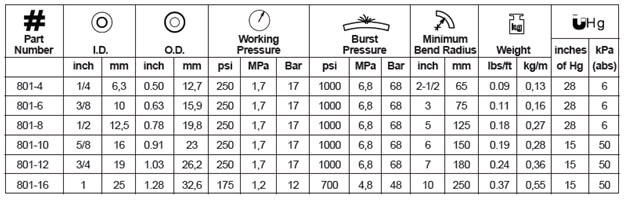

801 Color-Coded Hose

Made of the highest-quality elastomeric compounds for a lively feel, excellent flexibility and long-lasting service on the job. Construction:

Synthetic rubber tube; one textile braid reinforcement; MSHA accepted synthetic rubber cover. Furnished in gray, red, yellow, blue, green or black.

Application and Temperature Range:

Widely used for shop air systems and general industrial, maintenance and automotive applications.

Low-pressure service hose for use with:

* Petroleum-based hydraulic fluids and lubricating oils within a temperature range of -40°F to +212°F (-40°C to +100°C).

* Water, water/oil emulsion, and water/glycol hydraulic fluids up to +185°F (+85°C).

* Air within a temperature range of -40°F to 158°F (-40°C to +70°C).

Made of the highest-quality elastomeric compounds for a lively feel, excellent flexibility and long-lasting service on the job. Construction:

Synthetic rubber tube; one textile braid reinforcement; MSHA accepted synthetic rubber cover. Furnished in gray, red, yellow, blue, green or black.

Application and Temperature Range:

Widely used for shop air systems and general industrial, maintenance and automotive applications.

Low-pressure service hose for use with:

* Petroleum-based hydraulic fluids and lubricating oils within a temperature range of -40°F to +212°F (-40°C to +100°C).

* Water, water/oil emulsion, and water/glycol hydraulic fluids up to +185°F (+85°C).

* Air within a temperature range of -40°F to 158°F (-40°C to +70°C).

PKR Hose SAE 100 R5

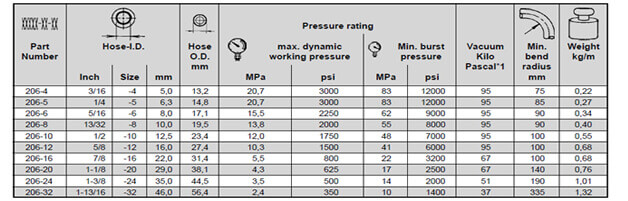

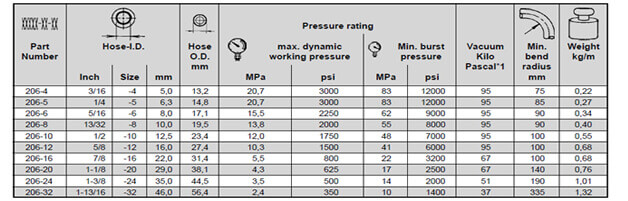

* 206 - No-Skive PKR® Hose

* SAE 100 R5 SAE J1402 All

* D.O.T. FMVSS 106-Air Brake Hose

Hose construction:

PKR® elastomer tube, textile inner braid, high tensile steel wire braid reinforcement; blue textile braid cover.

Temperature range:....................... -48 °C to +150 °C*

Exceptions: Air ....................................... max. +100 °C

Water* ................................... max. +85 °C

Applications

Medium pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water.

* 206 - No-Skive PKR® Hose

* SAE 100 R5 SAE J1402 All

* D.O.T. FMVSS 106-Air Brake Hose

Hose construction:

PKR® elastomer tube, textile inner braid, high tensile steel wire braid reinforcement; blue textile braid cover.

Temperature range:....................... -48 °C to +150 °C*

Exceptions: Air ....................................... max. +100 °C

Water* ................................... max. +85 °C

Applications

Medium pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water.

Marine Fuel and Engine Hose

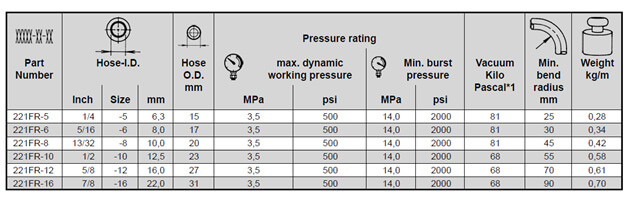

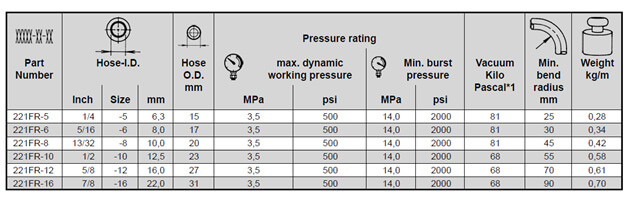

221FR - No-Skive Hose with fire resistant cover

Marine Fuel & Engine Hose meets SAE J1527 Type R3 USCG

Type A, SAE J1942 and ISO 7840

Hose construction:

Fuel and oil-resistant nitrile rubber tube, one braid high-tensile steel wire, and oil, weather and fire resistant synthetic blue, rubber cover. Layline is embossed for permanent identification.

Temperature range:....................... -20 °C to +100 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

Medium pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude, fuel oils and water.

Meets class 1 permeation requirements with gasoline and gasoline/ethanol blend and 2,5 minute fire test.

USCG accepted for commercial and recreational vessel applications.

221FR - No-Skive Hose with fire resistant cover

Marine Fuel & Engine Hose meets SAE J1527 Type R3 USCG

Type A, SAE J1942 and ISO 7840

Hose construction:

Fuel and oil-resistant nitrile rubber tube, one braid high-tensile steel wire, and oil, weather and fire resistant synthetic blue, rubber cover. Layline is embossed for permanent identification.

Temperature range:....................... -20 °C to +100 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

Medium pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude, fuel oils and water.

Meets class 1 permeation requirements with gasoline and gasoline/ethanol blend and 2,5 minute fire test.

USCG accepted for commercial and recreational vessel applications.

Air Conditioning and Refrigerant Hose

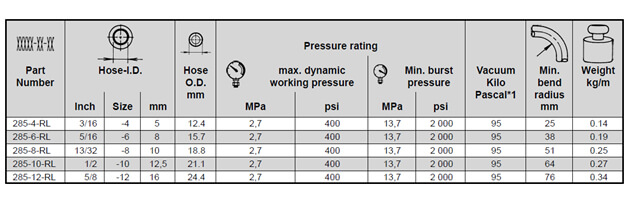

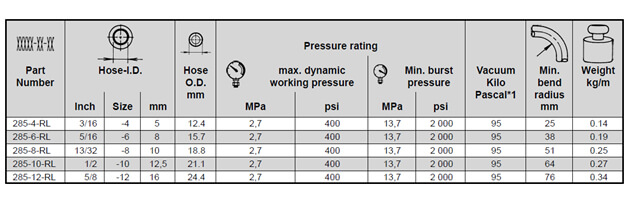

285 - No-Skive Hose

Air Conditioning and Refrigerant

SAE J2064 Typ C

Hose construction:

The hose has a nylon barrier between two elastomer layers, a fabric braid reinforcement and a heat, moisture and ozone resistant elastomer cover.

Temperature range:....................... -30 °C to +125 °C

Applications

For use with Freon refrigerants 12, 134a and 22.

285 - No-Skive Hose

Air Conditioning and Refrigerant

SAE J2064 Typ C

Hose construction:

The hose has a nylon barrier between two elastomer layers, a fabric braid reinforcement and a heat, moisture and ozone resistant elastomer cover.

Temperature range:....................... -30 °C to +125 °C

Applications

For use with Freon refrigerants 12, 134a and 22.

SAE 100 R2 AT

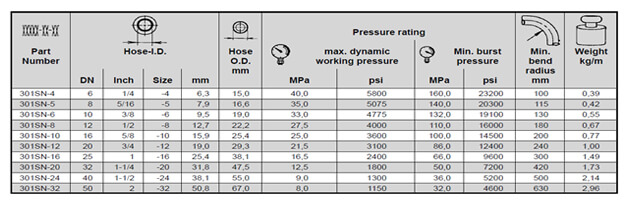

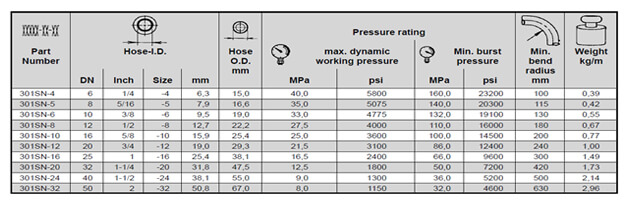

301SN - No-Skive Hose

ISO S 1436 / II / SAE 100 R2 AT

DIN 20 022 - 2SN / EN 853-2SN

Hose construction:

Synthetic rubber tube; two braids of high tensile steel wire reinforcement separated by a synthetic rubber layer; oil, weather and abrasion resistant synthetic rubber black outer cover.

Temperature range:....................... -40 °C to +100 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

High pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water. Pin prick cover for air or gas applications above 17 bar (250psi)

301SN - No-Skive Hose

ISO S 1436 / II / SAE 100 R2 AT

DIN 20 022 - 2SN / EN 853-2SN

Hose construction:

Synthetic rubber tube; two braids of high tensile steel wire reinforcement separated by a synthetic rubber layer; oil, weather and abrasion resistant synthetic rubber black outer cover.

Temperature range:....................... -40 °C to +100 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

High pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water. Pin prick cover for air or gas applications above 17 bar (250psi)

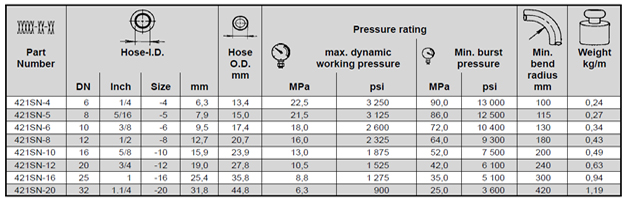

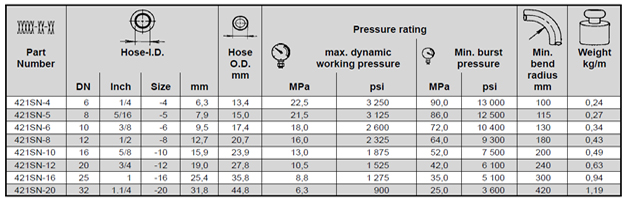

SAE 100 R1 AT

421SN - No-Skive Hose

SAE 100 R1 AT / DIN 20 022-1SN / EN 853-1SN

Hose construction:

Synthetic rubber tube; one braid of high tensile steel wire reinforcement; oil, weather and abrasion resistant black synthetic rubber cover.

Temperature range:....................... -40 °C to +100 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

High pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water. Pin prick cover for air or gas applications above 17 bar (250 psi).

421SN - No-Skive Hose

SAE 100 R1 AT / DIN 20 022-1SN / EN 853-1SN

Hose construction:

Synthetic rubber tube; one braid of high tensile steel wire reinforcement; oil, weather and abrasion resistant black synthetic rubber cover.

Temperature range:....................... -40 °C to +100 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

High pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water. Pin prick cover for air or gas applications above 17 bar (250 psi).

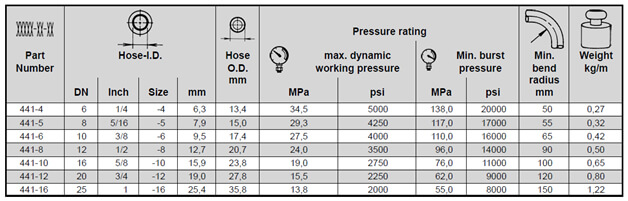

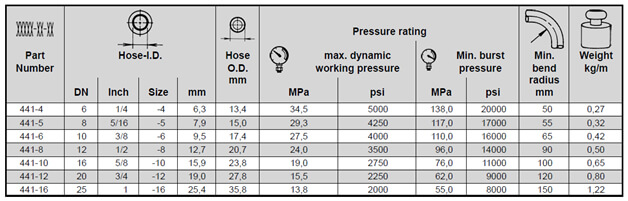

SAE 100 R16

441 - No-Skive 1-Layer Compact Hose

for small bend radii

SAE 100 R16, exceeds SAE 100 R2

Hose construction:

Synthetic Rubber tube; one braid of high tensile steel wire reinforcement; oil, weather and abrasion resistant black synthetic rubber cover.

Temperature range:....................... -40 °C to 100 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

High pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water. Pin prick cover for air or gas applications above 17 bar (250psi)

441 - No-Skive 1-Layer Compact Hose

for small bend radii

SAE 100 R16, exceeds SAE 100 R2

Hose construction:

Synthetic Rubber tube; one braid of high tensile steel wire reinforcement; oil, weather and abrasion resistant black synthetic rubber cover.

Temperature range:....................... -40 °C to 100 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

High pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water. Pin prick cover for air or gas applications above 17 bar (250psi)

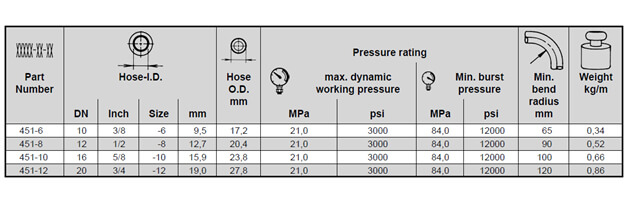

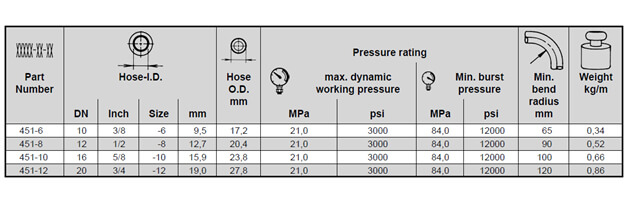

SAE 100 R17

451 - No-Skive Compact Hose

with constant pressure SAE 100 R17

Hose construction:

Synthetic rubber tube; one braid of high tensile steel wire reinforcement; oil, weather and abrasion resistant synthetic rubber cover.

Temperature range:....................... -40 °C to +100 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

High pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water. Pin prick cover for air or gas applications above 17bar (250 psi)

451 - No-Skive Compact Hose

with constant pressure SAE 100 R17

Hose construction:

Synthetic rubber tube; one braid of high tensile steel wire reinforcement; oil, weather and abrasion resistant synthetic rubber cover.

Temperature range:....................... -40 °C to +100 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

High pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water. Pin prick cover for air or gas applications above 17bar (250 psi)

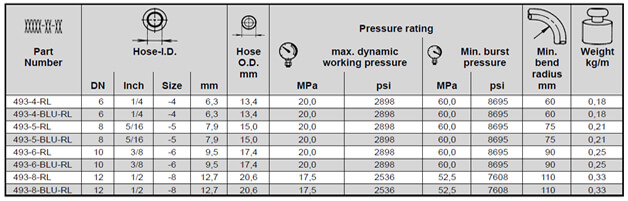

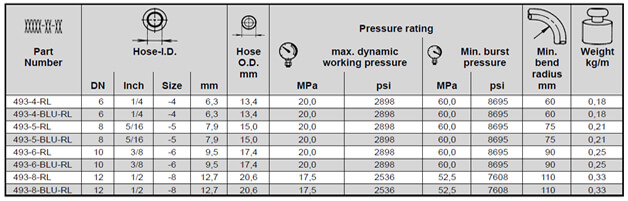

High Pressure Cleaning hose

493 - No-Skive High pressure cleaning hose

1-Layer

Hose construction:

Inner tube of synthetic rubber, a single braid of hightensile steel wire reinforcement and an oil and weather resistant black or blue (BLU) synthetic cover

Temperature range:

Exceptions: Water* ....................................... max. +70 °C

Applications

Designed for use with water only, for constant water temperatures up to 120°°C. The hose is not recommended for steam service.

493 - No-Skive High pressure cleaning hose

1-Layer

Hose construction:

Inner tube of synthetic rubber, a single braid of hightensile steel wire reinforcement and an oil and weather resistant black or blue (BLU) synthetic cover

Temperature range:

Exceptions: Water* ....................................... max. +70 °C

Applications

Designed for use with water only, for constant water temperatures up to 120°°C. The hose is not recommended for steam service.

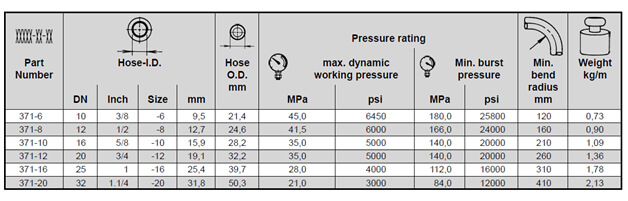

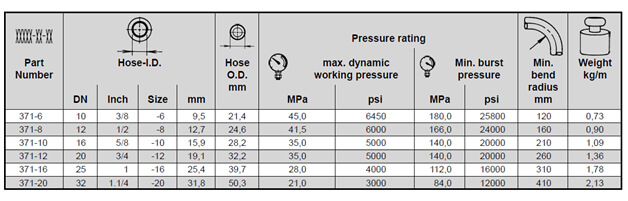

3-Wire Compact Hose with 4SP Pressure

371 - No-Skive Hose

3-Wire Compact Hose with 4SP pressure ratings

Hose construction:

Synthetic rubber tube;3 braids of high tensile steel wire reinforcement; oil, weather and abrasion resistant synthetic rubber cover.

Temperature range:....................... -40 °C to +100 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

Very high pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water. Pin prick cover for air or gas applications above 17 bar (250psi)

371 - No-Skive Hose

3-Wire Compact Hose with 4SP pressure ratings

Hose construction:

Synthetic rubber tube;3 braids of high tensile steel wire reinforcement; oil, weather and abrasion resistant synthetic rubber cover.

Temperature range:....................... -40 °C to +100 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

Very high pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water. Pin prick cover for air or gas applications above 17 bar (250psi)

SAE 100 R12

772ST - No-Skive High Pressure Hose

Super-Tough cover

Exceeds EN 856 R 12

Hose construction:

Consists of an inner tube of oil resistant Nitrile based synthetic rubber, 4 spiral plies of high tensile steel wire reinforcement and an oil and weather resistant, extremely abrasion-resistant special polymeric cover.

Temperature range:....................... -40 °C to +125 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

Very high pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water. Pin prick cover for air or gas applications above 17 bar (250psi)

772ST - No-Skive High Pressure Hose

Super-Tough cover

Exceeds EN 856 R 12

Hose construction:

Consists of an inner tube of oil resistant Nitrile based synthetic rubber, 4 spiral plies of high tensile steel wire reinforcement and an oil and weather resistant, extremely abrasion-resistant special polymeric cover.

Temperature range:....................... -40 °C to +125 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

Very high pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water. Pin prick cover for air or gas applications above 17 bar (250psi)

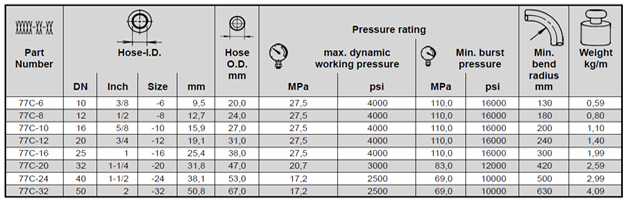

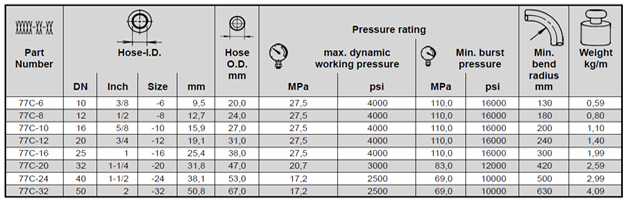

SAE 100 R13

77C/772* - No-Skive Multispiral Hose

Multispiral SAE 100 R12 / EN 856-R12

Hose construction:

Synthetic rubber inner tube; 4 spiral plies of high tensile steel wire reinforcement separated by synthetic rubber layers; weather and abrasion resistant synthetic rubber grey cover.

Temperature range:....................... -40 °C to +125 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

Very high pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water.

77C/772* - No-Skive Multispiral Hose

Multispiral SAE 100 R12 / EN 856-R12

Hose construction:

Synthetic rubber inner tube; 4 spiral plies of high tensile steel wire reinforcement separated by synthetic rubber layers; weather and abrasion resistant synthetic rubber grey cover.

Temperature range:....................... -40 °C to +125 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

Very high pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water.

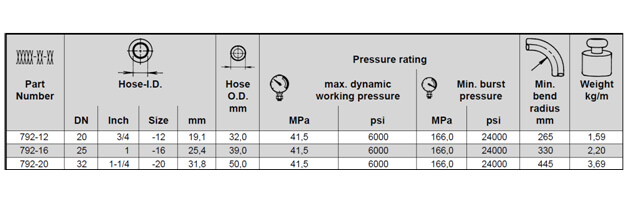

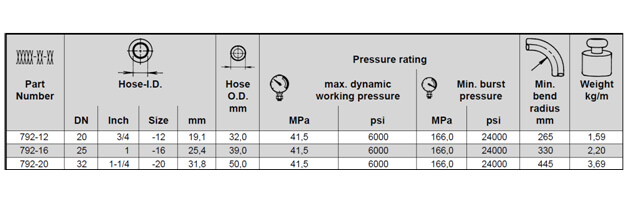

SAE 100 R15

792 - No-Skive Multispiral Hose

SAE 100 R15 / EN 856-R15

Hose construction:

Highly oil resistant nitrile rubber tube; 6 spiral plies of high tensile steel wire reinforcement separated by synthetic rubber layers; oil and weather resistant MSHA accepted synthetic rubber cover. Temperature range:....................... -40 °C to +125 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

Ultra high pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water.

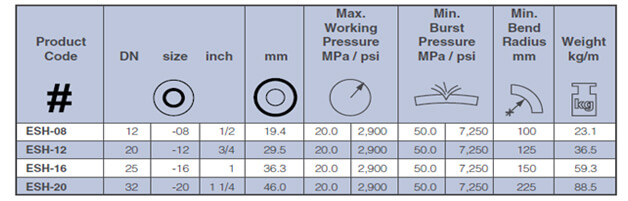

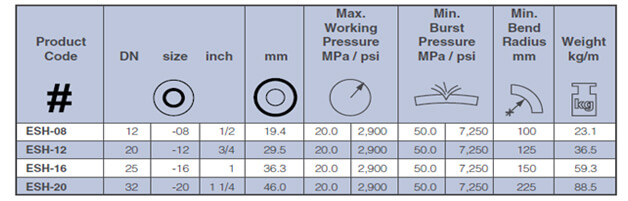

Sewer Cleaning hose

ESH – Sewer Cleaning Hose

Construction:

Core Tube:

Polyethylene compound, grey Pressure Reinforcement:

2 braided layers of high tensile synthetic yarn

Cover:

Polyurethane compound

Colour: yellow

Applications:

Hydrodynamic cleaning of sewers

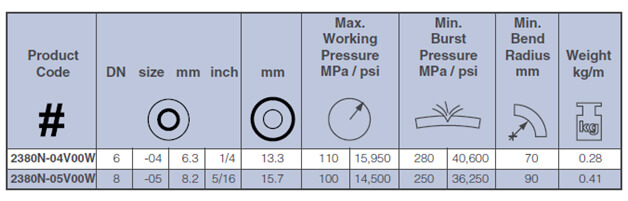

High Pressure Water Jet Hose

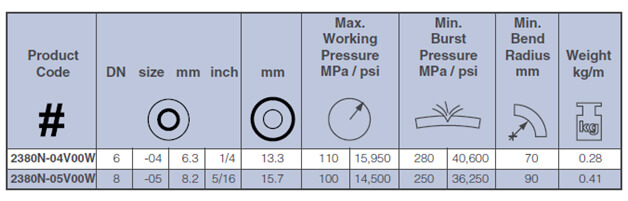

2380N – High Pressure Water Jetting Hose

Construction:

Core Tube:

Polyamide

Pressure Reinforcement:

Two spiral layers and two open spiral layers of high tensile steel wire.

Cover:

Polyurethane, black

Applications:

High pressure service for the construction and shipbuilding industries and for general industrial cleaning applications. Mainly used to remove different kinds of dirt accumulation, or materials from various surfaces, such as those in tanks, from concrete, asphalt, etc.

792 - No-Skive Multispiral Hose

SAE 100 R15 / EN 856-R15

Hose construction:

Highly oil resistant nitrile rubber tube; 6 spiral plies of high tensile steel wire reinforcement separated by synthetic rubber layers; oil and weather resistant MSHA accepted synthetic rubber cover. Temperature range:....................... -40 °C to +125 °C

Exceptions: Air ....................................... max. +70 °C

Water* ................................... max. +85 °C

Applications

Ultra high pressure service with petroleum based hydraulic fluids, water*-glycol and water*-oil emulsion hydraulic fluids, grease, lubricants, crude and fuel oils, air and water.

Sewer Cleaning hose

ESH – Sewer Cleaning Hose

Construction:

Core Tube:

Polyethylene compound, grey Pressure Reinforcement:

2 braided layers of high tensile synthetic yarn

Cover:

Polyurethane compound

Colour: yellow

Applications:

Hydrodynamic cleaning of sewers

High Pressure Water Jet Hose

2380N – High Pressure Water Jetting Hose

Construction:

Core Tube:

Polyamide

Pressure Reinforcement:

Two spiral layers and two open spiral layers of high tensile steel wire.

Cover:

Polyurethane, black

Applications:

High pressure service for the construction and shipbuilding industries and for general industrial cleaning applications. Mainly used to remove different kinds of dirt accumulation, or materials from various surfaces, such as those in tanks, from concrete, asphalt, etc.